The Makers | McGee & Co. x Filling Spaces

Sisters thoughtfully craft textiles to make a statement.

28 September 2023 -

McGee & Co. x Filling Spaces is our latest collaboration, debuting alongside our McGee & Co. Holiday 2023 Collection. What an incredible experience it has been partnering with the founders of this company, sisters Deepali Kalia and Nanu Khanna. The five-piece collection features the hand-drawn, block-printed patterns Filling Spaces is known for, a technique made famous by India, where Deepali and Nanu were raised. After launching the company in 2008, Filling Spaces grew at a pace that allowed the sisters to turn it from a passion project to their full-time jobs. Deepali is now based in Portland, Oregon, and is the designer of the company, hand-sketching patterns that are then made into blocks and applied to textiles by a team of artisans in Delhi and Jaipur. Nanu manages the company from India, focusing her time on building a company based on female empowerment and overseeing the process of creating textiles using traditional Indian handloom techniques. We sat down with the sisters to hear the origins of Filling Spaces and the challenges of running a business from afar.

What is it like being a female entrepreneur in India?

Filling Spaces: In India, no matter what level you are, home is always a priority. Your career comes next. If you want to move from one town to another, from one country to another, you have to get your family’s consent. If it’s a man, they just have to say, “We’re wrapping things up here and we’re moving.” It isn’t as simple for a woman. Even in the U.S., women are still struggling to balance family and careers. There’s more pressure on women in the workplace and it’s often that family should be considered first.

How did the McGee & Co. collaboration come to be?

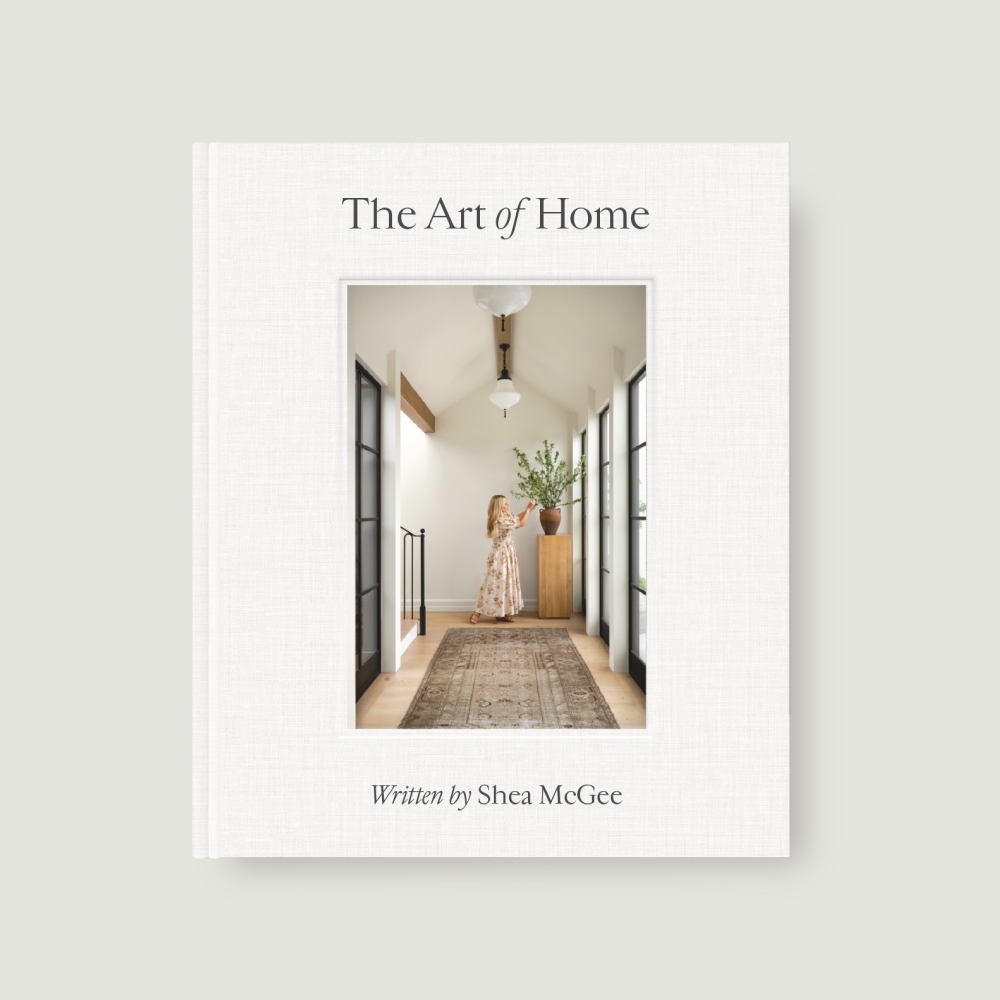

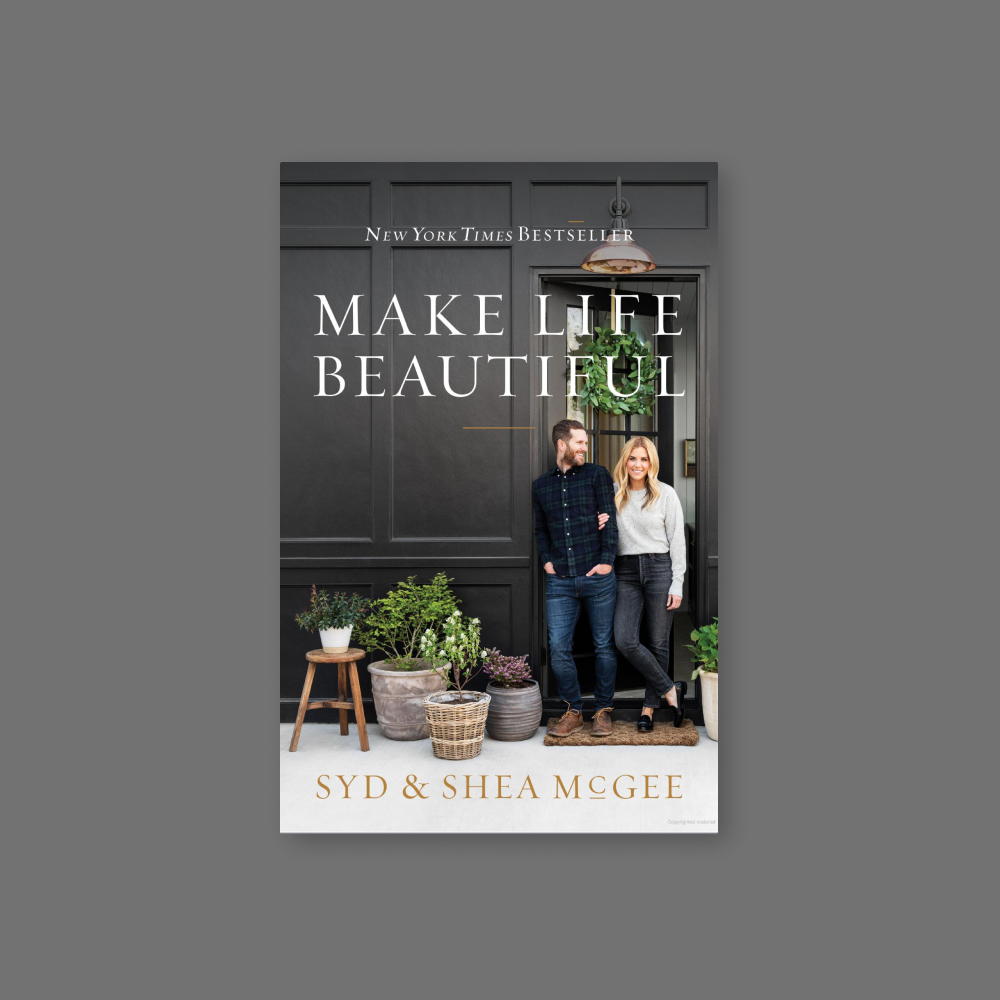

Filling Spaces: We first met Shea at a trade show in Atlanta. It was a long time ago when she first started doing YouTube videos. She was famous but not at the level she is now. She passed by our booth and we were super excited to see her. She came up to our table and said, “Oh I love them” and I was like, “Oh I love you! I love watching your videos!” From there, she started buying our pillows and we’ve done a lot of business with McGee & Co. Then we were given a chance to design a collaboration, and it was a dream come true. It started with a color palette, a little bit of a mood board, and some floral prints. I (Deepali) hand drew some of the designs and Nanu got the blocks made and printed. The rest is history.

How do you want your products to be used in people’s lives and homes?

Filling Spaces: It’s like Studio McGee says, Make Life Beautiful. It’s the same way we feel with our products. We want you to hear our story and how attached we are to everything we make. We put our hearts into every single collection and every single pattern. We want people to be happy, to respect the artisans, and to respect the raw quality.

Walk us through the production process.

Filling Spaces: We always start with drawings. I (Deepali) will hand draw the patterns and then we look at the repeats and incorporate colors. Then the drawings go to Nanu in India and she gets them hand-carved on blocks. We start to test the colors, and some are successes, others are failures. We keep designing until we have a good collection of seven or eight prints. During this process, we’re hand-looming fabrics and then they’re printed with the patterns we choose for the collection. We do small batches of fabric, maybe five to ten yards are printed. From there, the fabric is cut to shape, depending on whether it’s a square or lumbar pillow, draperies, or just fabric by the yard. For one collection, start to finish, it is anywhere from six to eight weeks for the end product.

No waste is a pillar of the company. Explain.

Filling Spaces: When we talk about no waste, we are not just talking about the fabric, we are also talking about the colors, the dyes, the printing. Since everything is block printed by hand, in one day only 20 yards (or so) of fabric is printed. We only make what is needed to fulfill the order.

Since it is all done in-house, there is no misprinting. Everything is tested on a small yard. If there is a yard or two left, we apply it to our Katran project. This is where we make products of the leftovers, it could be pillows, throws, or a bag. We gift our customers with unique bags made from the leftover fabric, and we make ribbons out of them. Not wasting fabric is so important to us.

The Makers | McGee & Co. x Filling Spaces

Orchid Floral Pillow Cover

Olive Lotus Stocking

Teal Lotus Floral Pillow Cover